Apple suppliers ipad airpods production – Apple Suppliers: iPad & AirPod Production – a deep dive into the intricate global network that brings your favorite Apple gadgets to life. From the sourcing of minuscule components to the massive assembly plants, the journey of an iPad or AirPods is a fascinating example of modern manufacturing prowess. We’ll unpack the complexities of Apple’s supply chain, exploring the key players, geographical distribution, and the ever-evolving technological advancements shaping this multi-billion dollar industry.

This exploration delves into the relationships between Apple and its suppliers, examining the potential risks and rewards inherent in such a tightly interwoven system. We’ll also touch upon the environmental and social implications of this massive production operation, considering Apple’s commitment to sustainability and ethical sourcing. Get ready to unravel the secrets behind the seamless production of your beloved Apple devices.

AirPod Production and Supply

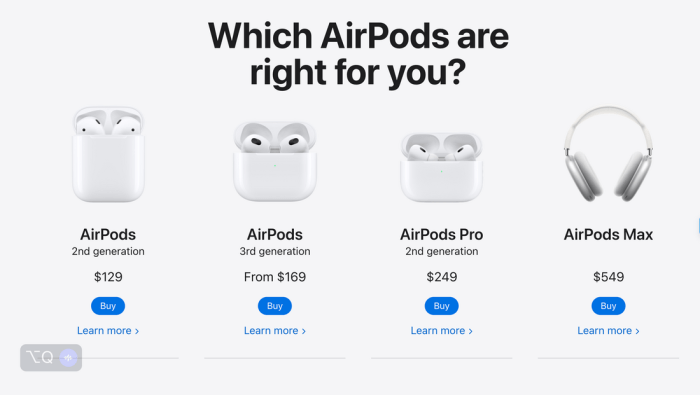

Apple’s AirPods have become a ubiquitous symbol of modern tech, but the journey from design concept to consumer ear is a complex global operation involving numerous suppliers and intricate logistical networks. Understanding this supply chain is crucial for comprehending the product’s pricing, availability, and potential vulnerabilities. This section delves into the specifics of AirPod production and the factors influencing it.

The production of AirPods involves a vast network of suppliers, each contributing specialized components. These components are then assembled by Apple’s manufacturing partners, primarily located in Asia. Geopolitical events and global economic conditions significantly impact this delicate ecosystem.

AirPod Component Suppliers

Identifying the precise suppliers for every AirPod component is challenging due to Apple’s strict confidentiality. However, based on industry analysis and publicly available information, we can highlight some key players and their likely contributions:

- Chips: TSMC (Taiwan Semiconductor Manufacturing Company) is a highly probable supplier for the key system-on-a-chip (SoC) powering AirPods functionality. Broadcom and other companies likely contribute additional chipsets for Bluetooth, audio processing, and other features.

- Batteries: Several companies, likely including those based in China and South Korea, are responsible for supplying the lithium-ion batteries that power AirPods. The specific suppliers are generally kept confidential by Apple.

- Microphones: The precise suppliers of the microphones used in AirPods are undisclosed, but the industry is dominated by a few major players, many based in Asia, specializing in miniature microphones for consumer electronics.

Geopolitical Factors and AirPod Production, Apple suppliers ipad airpods production

The global nature of AirPod production exposes it to various geopolitical risks. Disruptions in any part of the supply chain can significantly impact production and delivery. For example, heightened US-China tensions, trade wars, or pandemic-related lockdowns in key manufacturing hubs can cause delays and shortages. Natural disasters in supplier regions also pose a considerable threat.

Apple employs several mitigation strategies to reduce these risks. These include: diversifying its supplier base to reduce reliance on single sources; maintaining strategic stockpiles of key components; developing alternative manufacturing locations; and investing in robust logistics and supply chain management systems. However, complete risk elimination is virtually impossible in such a complex global network.

AirPod Production Capacity Across Manufacturing Partners

Estimating the precise production capacity of each Apple manufacturing partner is difficult due to the confidential nature of such agreements. However, based on industry reports and estimations, we can present a hypothetical example to illustrate the scale of operations. Remember, these figures are illustrative and may not reflect actual production numbers.

| Partner | Location | Production Capacity (units/year) | Product Focus |

|---|---|---|---|

| Foxconn | China | 150,000,000 | AirPods 2, AirPods (3rd generation) |

| Luxshare Precision | China | 100,000,000 | AirPods Pro, AirPods Max |

| GoerTek | China | 75,000,000 | AirPods 2, AirPods (3rd generation) |

| Pegatron | China | 50,000,000 | AirPods (3rd generation), AirPods Pro |

Technological Advancements and Impact on Supply Chain: Apple Suppliers Ipad Airpods Production

The relentless march of technology significantly impacts the production of Apple’s iconic devices, the iPad and AirPods. Advancements in various fields, from battery technology to automation, are reshaping the manufacturing landscape, influencing both the cost and complexity of these products. This section will delve into the specific ways technological progress is affecting the supply chain of these popular Apple gadgets.

Battery Technology’s Influence on iPad and AirPod Production

Improvements in battery technology directly affect the design, performance, and ultimately, the production cost of both iPads and AirPods. The development of higher energy density batteries allows for thinner and lighter devices, impacting the iPad’s form factor and enabling longer battery life in AirPods. This, in turn, influences manufacturing processes; for example, the need for smaller, more precisely placed battery components in AirPods requires more sophisticated assembly techniques. Conversely, advancements in fast-charging technology necessitate the integration of specialized charging circuitry and components, adding to the manufacturing complexity and cost, but ultimately offering a superior user experience that justifies the investment. For example, the shift from older Lithium-ion battery chemistries to more advanced Lithium-polymer batteries in iPads has allowed for increased capacity without a significant increase in size or weight, streamlining the manufacturing process while improving product performance.

Miniaturization’s Impact on AirPod Production Complexity and Cost

The remarkable miniaturization of components within AirPods significantly increases the complexity and cost of their production. Packing sophisticated audio technology, microphones, sensors, and batteries into such a small form factor demands incredibly precise manufacturing processes. This necessitates the use of advanced micro-assembly techniques, specialized tooling, and highly skilled labor. The smaller the components, the more challenging it is to handle and assemble them, leading to higher manufacturing costs and a lower tolerance for error. For instance, the precise placement of the tiny microphones within the AirPod housing requires robotic precision and advanced quality control measures to ensure consistent sound quality across all units. A single misplaced component could render an entire AirPod unusable, highlighting the high stakes involved in this miniaturization process.

Automation and Robotics in iPad and AirPod Manufacturing

Automation and robotics are transforming the manufacturing processes for both iPads and AirPods. These technologies increase efficiency, improve precision, and reduce labor costs. However, the level of automation varies across different manufacturing stages.

| Manufacturing Stage | iPad Automation Level | AirPod Automation Level |

|---|---|---|

| Component Sourcing & Assembly | High – Automated material handling, component placement | Very High – Highly automated assembly lines with robotic precision |

| Testing and Quality Control | High – Automated testing systems for various functionalities | Very High – Automated acoustic and functional testing, microscopic inspection |

| Packaging and Shipping | High – Automated packaging lines and logistics systems | High – Automated packaging and sorting systems |

The table illustrates that while both iPad and AirPod production leverage automation extensively, the level is generally higher for AirPods due to the increased precision and complexity demanded by their miniaturized design. This reflects the industry trend towards higher automation in the manufacturing of smaller, more intricate electronic devices. For example, the use of collaborative robots (cobots) in AirPod assembly allows for human-robot interaction in tasks requiring dexterity, while automated vision systems ensure consistent quality control throughout the production process.

Ultimately, understanding the Apple Suppliers: iPad & AirPod Production chain reveals a complex interplay of global economics, technological innovation, and ethical considerations. From the geopolitical risks to the advancements in automation, every aspect contributes to the final product you hold in your hand. The journey from raw materials to finished goods is a testament to human ingenuity and global collaboration, highlighting both the remarkable efficiency and the inherent vulnerabilities of this intricate system. The future of Apple’s production relies on continuous adaptation and a commitment to sustainable and ethical practices.

Blockchain Network Berita Teknologi Terbaru

Blockchain Network Berita Teknologi Terbaru