Researchers turn seawater hydrogen fuel – Researchers turn seawater into hydrogen fuel: A groundbreaking leap forward in clean energy? Forget expensive and resource-intensive hydrogen production methods. Scientists are now exploring the vast, untapped potential of seawater as a hydrogen source, promising a cleaner, more sustainable future. This innovative approach tackles both the energy crisis and environmental concerns head-on, offering a glimpse into a world powered by the ocean’s boundless energy.

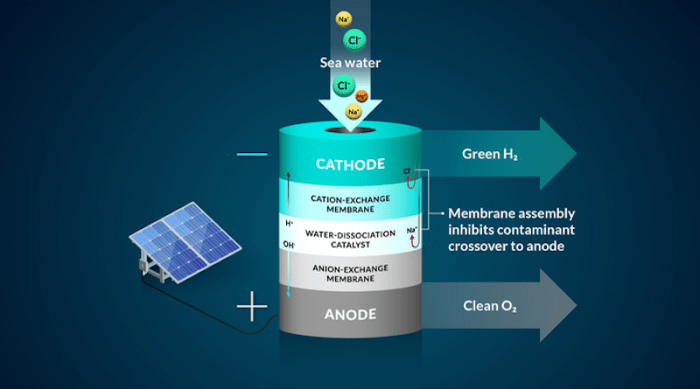

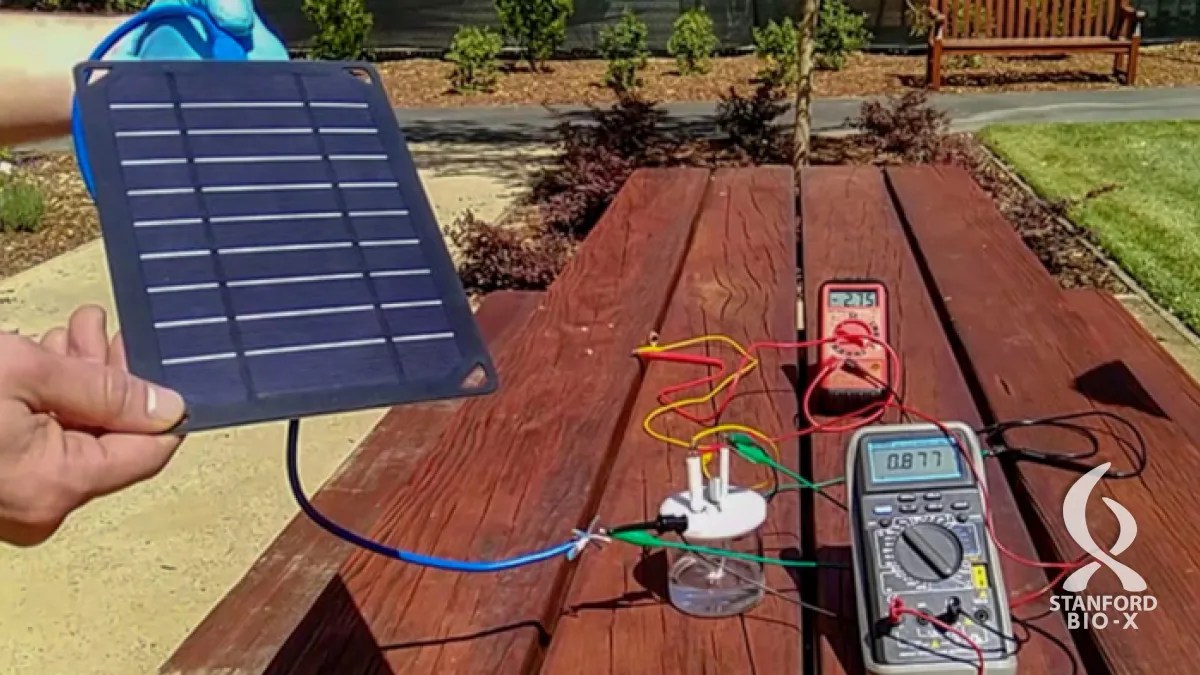

The process involves extracting hydrogen from seawater through electrolysis, a method that splits water molecules into hydrogen and oxygen using electricity. While the concept isn’t new, recent advancements in catalyst technology and membrane design have significantly boosted efficiency and lowered costs, making seawater-based hydrogen production a realistic contender in the renewable energy race. This isn’t just about creating a new fuel source; it’s about revolutionizing how we approach energy production and consumption.

Introduction to Seawater-Based Hydrogen Fuel

The quest for clean and sustainable energy sources is driving intense research into hydrogen fuel, a promising alternative to fossil fuels. Hydrogen’s high energy density and zero-emission combustion make it an attractive option, but its production methods often rely on energy-intensive processes, hindering its widespread adoption. Seawater, covering over 70% of the Earth’s surface, presents a readily available and virtually inexhaustible resource for hydrogen production, offering a compelling solution to this challenge.

Seawater electrolysis, a process that uses electricity to split seawater into hydrogen and oxygen, is a key technology in this field. However, the presence of salts and other impurities in seawater poses significant challenges. Corrosion of electrolyzer components is a major concern, demanding the development of robust and durable materials. Furthermore, the energy efficiency of seawater electrolysis needs improvement to compete economically with established hydrogen production methods. Despite these hurdles, the vast potential of seawater as a hydrogen source presents exciting opportunities for innovation and technological advancement, potentially revolutionizing the energy landscape.

Challenges of Seawater Electrolysis

The salinity of seawater introduces complexities not encountered in freshwater electrolysis. The presence of dissolved salts can lead to scaling and fouling on the electrodes, reducing efficiency and lifespan. Chlorine evolution at the anode is another significant issue, as chlorine is corrosive and can damage the electrolyzer. Researchers are actively exploring innovative electrode materials and membrane technologies to mitigate these problems. For example, the development of specialized coatings and the use of anion exchange membranes (AEMs) are showing promise in improving the durability and efficiency of seawater electrolyzers. These advancements are crucial for making seawater-based hydrogen production economically viable.

Environmental Benefits of Seawater Hydrogen Fuel

Compared to fossil fuels, seawater-based hydrogen fuel offers significant environmental advantages. Its combustion produces only water vapor, eliminating greenhouse gas emissions that contribute to climate change. Unlike fossil fuel extraction, which often results in habitat destruction and pollution, seawater electrolysis has a significantly lower environmental footprint. While the energy used for electrolysis must be sourced sustainably (e.g., from renewable sources like solar or wind power) to realize the full environmental benefits, the potential for a truly clean and sustainable energy cycle is undeniable. This contrasts sharply with the air and water pollution, carbon emissions, and land degradation associated with the extraction, processing, and combustion of fossil fuels. The shift to seawater-based hydrogen represents a significant step towards a greener future.

Economic and Infrastructure Considerations: Researchers Turn Seawater Hydrogen Fuel

The viability of seawater-based hydrogen fuel hinges not only on the technological feasibility but also on its economic competitiveness and the infrastructure required for its widespread adoption. A successful transition necessitates a careful assessment of costs and a strategic plan for infrastructure development. While the technology shows promise, the economic landscape and the logistical hurdles involved are significant factors that will determine its ultimate success.

The economic viability of seawater hydrogen production is highly dependent on scale. Small-scale operations, perhaps for isolated communities or niche applications, will likely face higher production costs due to economies of scale. Larger-scale facilities, however, could potentially achieve cost parity with, or even undercut, fossil fuel-based hydrogen production. This would depend on several key factors, including technological advancements leading to increased efficiency and reduced capital expenditure.

Cost Breakdown of a Seawater Hydrogen Production Facility

Establishing a seawater hydrogen production facility involves substantial upfront investment and ongoing operational costs. A realistic cost assessment is crucial for attracting investors and ensuring long-term sustainability. The following provides a broad overview of the key cost components:

- Land Acquisition: The cost of land acquisition will vary significantly depending on location. Coastal areas with suitable access to seawater and infrastructure are likely to be more expensive. For example, a facility located near a major port might require a substantial investment in land purchase or lease compared to a more remote site. The proximity to existing infrastructure (power grids, transportation networks) will influence this cost.

- Equipment Costs: This is a major expense, encompassing the cost of electrolyzers, seawater pre-treatment systems, hydrogen storage tanks, and other ancillary equipment. The choice of electrolyzer technology (alkaline, PEM, etc.) significantly impacts this cost, with some technologies currently being more expensive than others. Technological advancements are continuously driving down the cost of electrolyzers, but it remains a significant portion of the initial investment.

- Operational Expenses: These include the costs of electricity, seawater intake and treatment, labor, and maintenance of the equipment. Electricity consumption is a critical factor, as electrolyzer efficiency directly impacts energy costs. The cost of labor will vary depending on location and the skill level required. Seawater pre-treatment costs can be substantial depending on the quality of the water source and the level of purification needed.

- Maintenance: Regular maintenance is essential to ensure the long-term operation and efficiency of the facility. This includes scheduled maintenance, repairs, and potential replacements of components. The frequency and cost of maintenance will depend on the technology employed and the operating conditions.

Necessary Infrastructure Developments

Widespread adoption of seawater hydrogen fuel necessitates significant infrastructure development. This is not simply a matter of building production facilities; it requires a comprehensive approach addressing transportation, storage, and distribution.

One key challenge is the development of a robust hydrogen distribution network. This might involve the construction of pipelines for transporting hydrogen over long distances, the adaptation of existing natural gas pipelines, or the use of hydrogen carriers such as ammonia or liquid organic hydrogen carriers (LOHCs). The development of safe and efficient hydrogen storage solutions, including both large-scale storage facilities and smaller-scale on-site storage tanks, is also crucial. Furthermore, integration with existing energy grids is essential to ensure reliable power supply to the production facilities and to manage the intermittent nature of renewable energy sources often used to power electrolysis.

Future Prospects and Research Directions

The nascent field of seawater-based hydrogen fuel holds immense promise, but significant hurdles remain before it becomes a commercially viable energy source. Overcoming these challenges requires a concerted effort focusing on several key research areas and strategic collaborations. Successful implementation will not only revolutionize energy production but also reshape global energy infrastructure.

The path forward necessitates advancements across multiple disciplines, from materials science to large-scale engineering. Addressing these complexities will unlock the potential of this revolutionary technology, paving the way for a sustainable energy future.

Key Research Areas Requiring Further Investigation

Several crucial areas demand focused research efforts to improve the efficiency and cost-effectiveness of seawater hydrogen production. These include optimizing electrolysis processes for seawater’s unique challenges, developing robust and durable materials resistant to corrosion, and scaling up production to meet industrial demands. Further research into advanced energy storage solutions tailored for seawater-derived hydrogen is also vital.

- Electrocatalyst Development: Research into more efficient and durable electrocatalysts is crucial for lowering energy consumption during the electrolysis process. Current catalysts often suffer from degradation in the presence of seawater’s impurities. The development of robust and cost-effective catalysts tailored to seawater electrolysis is paramount.

- Membrane Technology: Improved membrane technologies are needed to enhance the separation of hydrogen and oxygen gases produced during electrolysis. Current membranes can be susceptible to fouling and degradation by seawater constituents. Research focuses on developing more resilient and selective membranes with longer operational lifetimes.

- Corrosion Mitigation: Seawater’s corrosive nature poses a significant challenge to the longevity of electrolysis systems. Developing corrosion-resistant materials and protective coatings is essential for reducing maintenance costs and ensuring long-term system reliability. Research into novel alloys and protective coatings is a key priority.

- Energy Storage Solutions: Efficient and cost-effective energy storage solutions are crucial for managing the intermittent nature of renewable energy sources used to power seawater electrolysis. Research into advanced hydrogen storage technologies, such as high-pressure tanks or liquid hydrogen storage, is necessary for seamless integration into the energy grid.

Potential Applications of Seawater-Derived Hydrogen Fuel

Seawater-derived hydrogen fuel possesses the potential to revolutionize various sectors, offering a clean and sustainable alternative to fossil fuels. Its versatility makes it suitable for a wide range of applications, from powering transportation systems to providing energy storage solutions for the grid. This widespread applicability underscores the technology’s transformative potential.

- Transportation: Seawater hydrogen can fuel fuel cell vehicles, offering a zero-emission alternative to gasoline-powered cars and trucks. This could significantly reduce greenhouse gas emissions from the transportation sector. Imagine a future where hydrogen-powered ships and airplanes contribute to cleaner skies and oceans.

- Energy Storage: Seawater hydrogen can serve as a crucial energy storage medium for intermittent renewable energy sources like solar and wind power. This allows for the efficient storage and later retrieval of excess energy, addressing the intermittency challenge and ensuring a stable energy supply. Examples include large-scale hydrogen storage facilities integrated with renewable energy farms.

- Industrial Processes: Hydrogen produced from seawater can replace fossil fuels in various industrial processes, such as ammonia production and steel manufacturing. This transition would drastically reduce carbon emissions from these energy-intensive sectors. The shift to hydrogen-based industrial processes is already underway in several countries.

Collaboration for Accelerated Development and Deployment, Researchers turn seawater hydrogen fuel

The successful development and deployment of seawater hydrogen technology require a collaborative effort between researchers, industries, and governments. This collaborative approach is crucial for overcoming technical challenges, securing funding, and establishing the necessary infrastructure for widespread adoption. A synergistic approach across sectors is vital.

The creation of public-private partnerships will foster innovation, attract investment, and expedite the commercialization process. Governments can play a critical role by providing funding for research and development, establishing supportive policies, and investing in the necessary infrastructure. Industry involvement is essential for scaling up production, developing commercial applications, and ensuring market penetration. A coordinated strategy involving all stakeholders is crucial for successful implementation.

The quest to harness seawater’s hydrogen potential is far from over, but the progress is undeniably exciting. As researchers continue to refine the process and address remaining challenges, the prospect of a clean, abundant, and sustainable energy source derived from the ocean becomes increasingly tangible. This isn’t just a technological breakthrough; it’s a testament to human ingenuity and our unwavering commitment to a greener planet. The future of energy may well be salty, and that’s a pretty cool wave to ride.

Blockchain Network Berita Teknologi Terbaru

Blockchain Network Berita Teknologi Terbaru